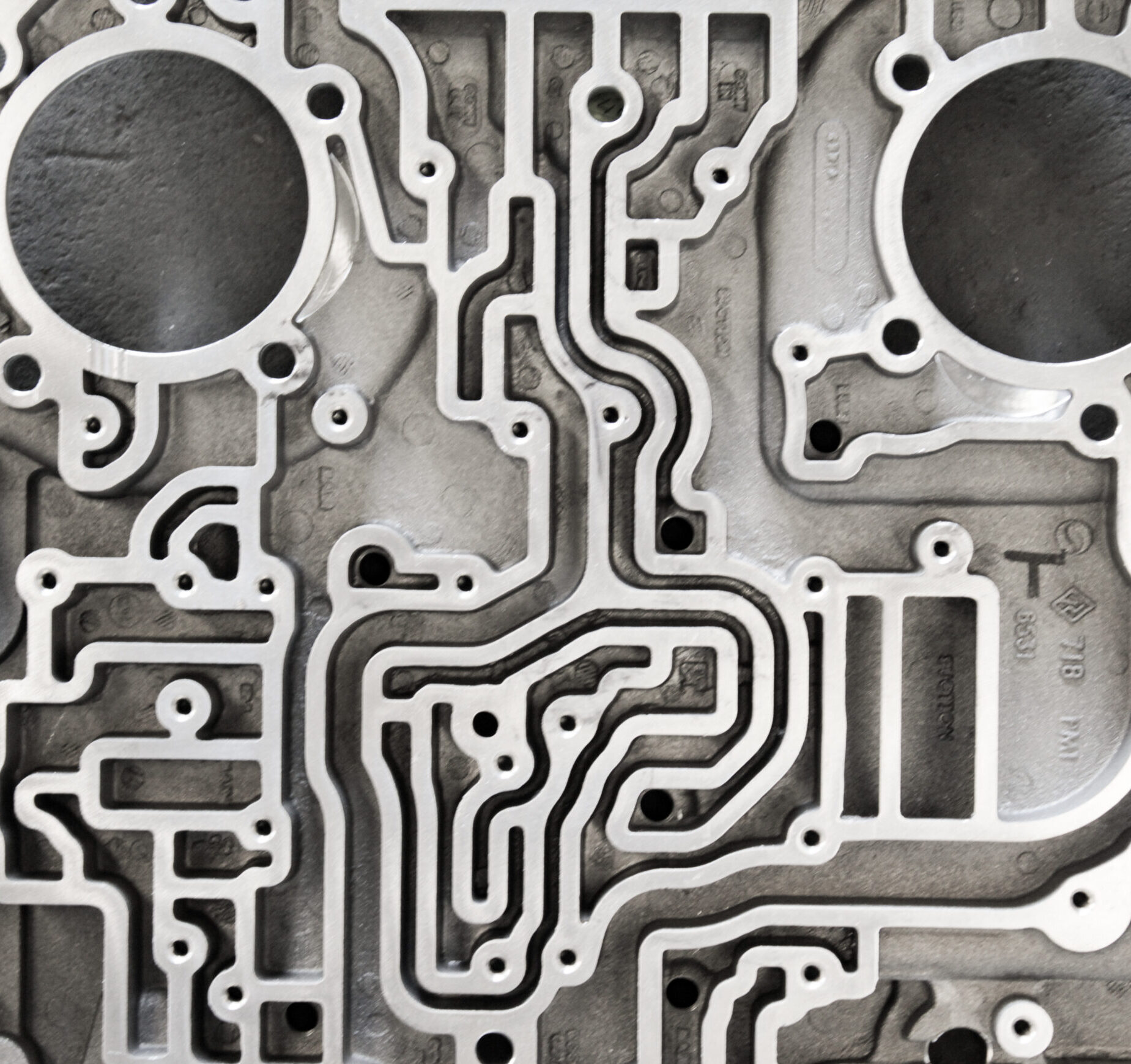

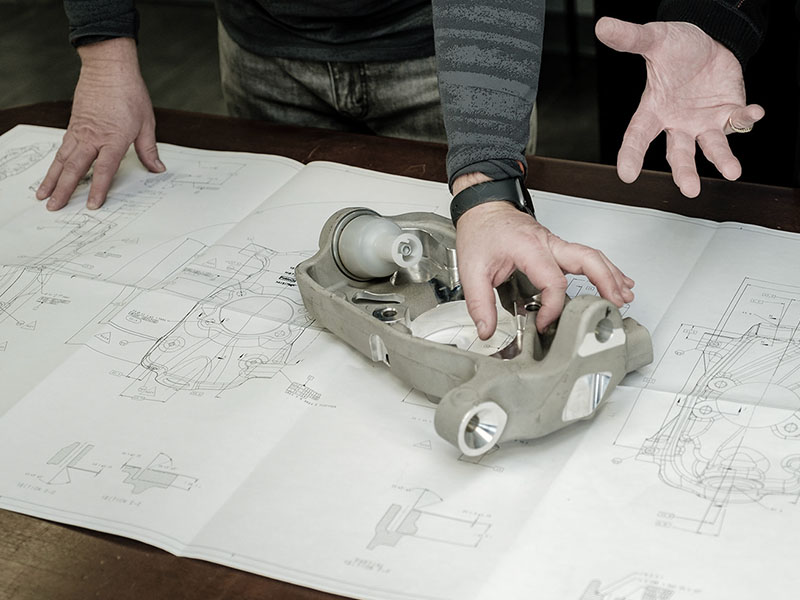

Optimizing the part and process designs is the starting point for every casting project.

We have the knowledge and experience to translate customer specifications into robust designs that will lead to dependable production of high-performance parts.

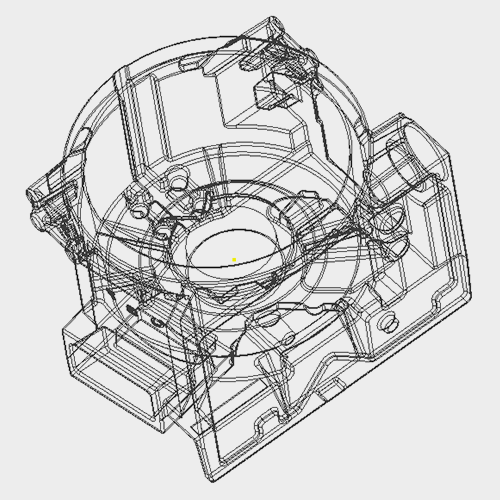

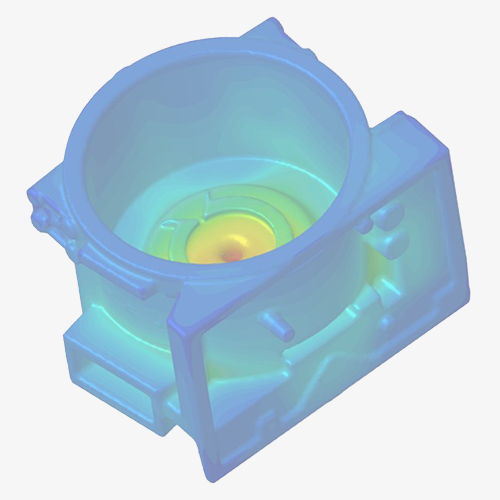

SIMULATION

Our simulation capabilities allow us to plan, test, and validate part and process designs before they reach the plant floor.

TOOLING DESIGN

Our in-house tooling capabilities enable us to create customized tooling for each new project in an efficient and cost-effective manner.

PROCESS SELECTION

Our team has the technical expertise to select the optimal casting process based on customer requirements and project parameters.

We invest in the latest technologies to give our experienced team the tools to work smarter, faster, and better.

Technology is incorporated throughout our modern operations, from part design and process simulation to production automation and quality assurance.

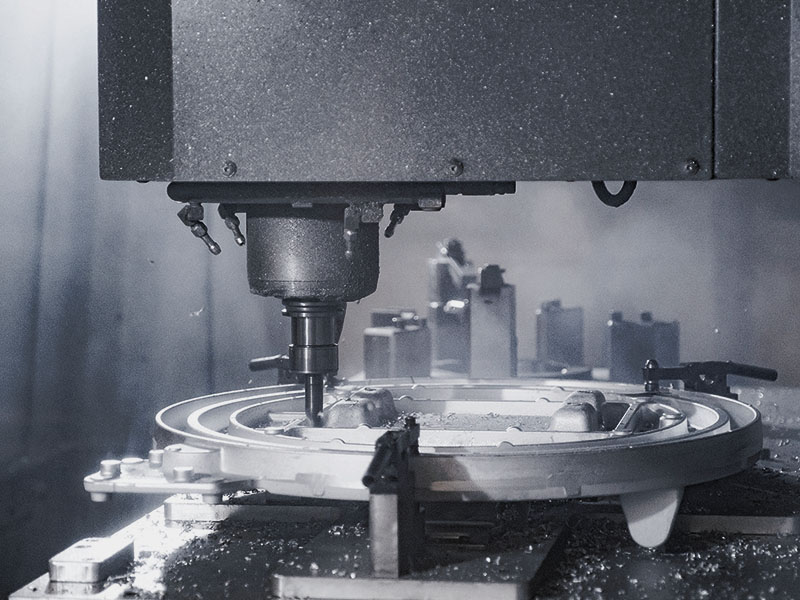

IN-HOUSE TOOLING

We integrate specialized technologies into our tooling capabilities to deliver superior results. For example, we can use water cooling to achieve highly controlled and targeted solidification during the casting process.

PROCESS DATA

We use sensors throughout our casting processes to obtain detailed real-time data about temperature, pressure, and other critical metrics. We use this data for performance monitoring, quality control, and troubleshooting.

AUTOMATION

We implement different forms of automation using robotics, CNC equipment, and other technologies to optimize our casting processes and meet specific project requirements.

As a company, we’ve been honing our craft since 1946, and many of our team members have decades of aluminum casting experience.

Our expertise is reflected in our strong operational capabilities and our ability to communicate, collaborate, and problem solve with our customers at an expert level.

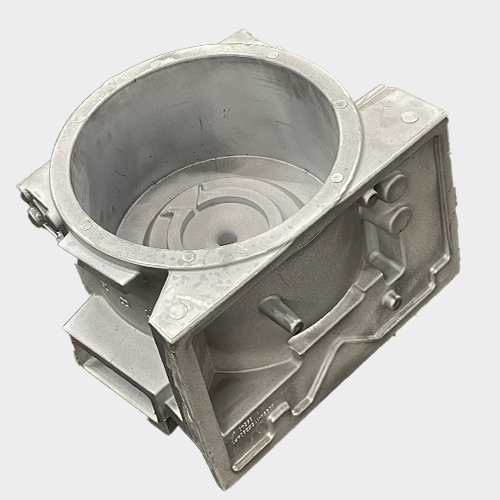

CASTING PROCESSES

We offer a range of casting processes and work with our customers to identify the ideal process for each part based on their functional, performance, and business needs.

• Permanent mold

• Semi-permanent mold

• Low-pressure permanent mold

• Tilt pour permanent mold

HEAT TREATING

We have advanced heat treating capabilities that allow us to produce parts to meet specific requirements related to structure, strength, and performance.

We are committed to high quality standards throughout our organization, from the parts we produce to our customer experience.

We recognize that our customers depend on us to provide top-quality parts, so our team strives every day to deliver the best possible work.

CUSTOMER FOCUS

Our customers don’t rely on us for parts; instead, they rely on us for a trusted partnership.

We focus not only on producing top-quality parts, but also on ensuring these parts fit seamlessly into our customers’ processes and products.

SYSTEMS & STANDARDS

We are certified under a number of safety and quality systems and standards, including:

• ISO9001